The Innovation Project

Sustainable Concretes for Lightweight Constructions

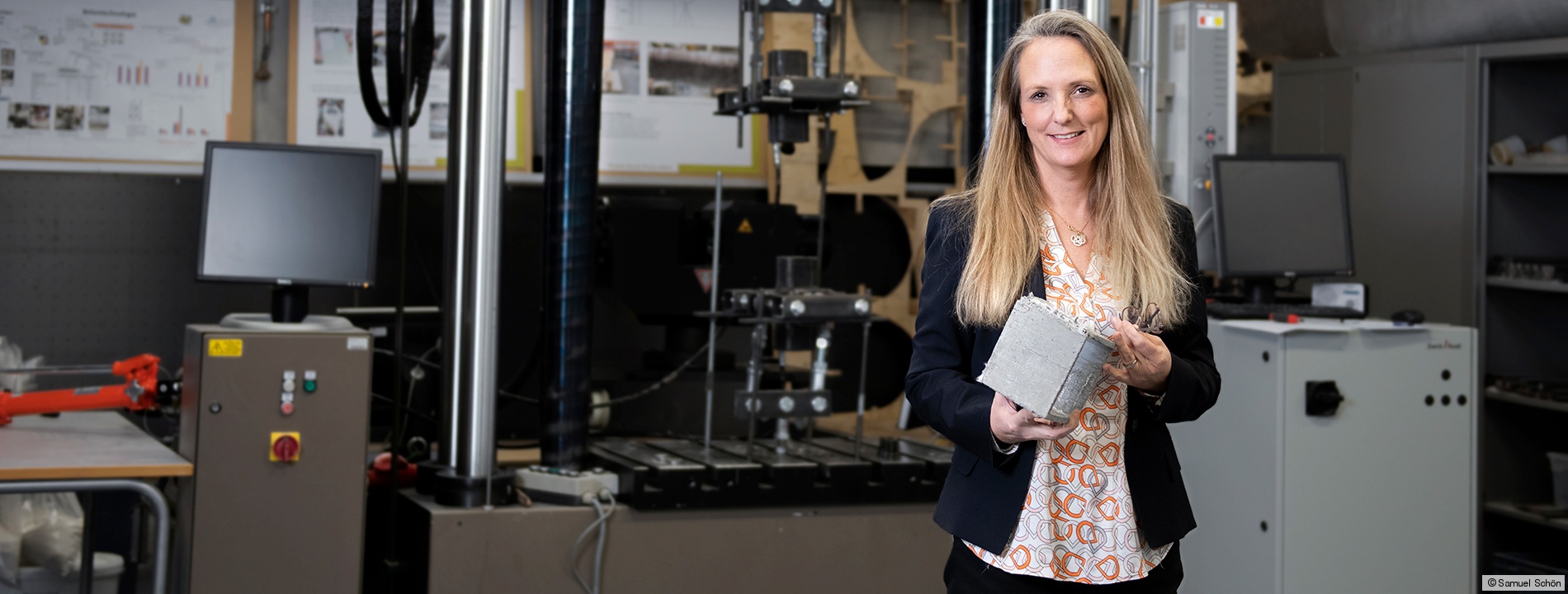

During her innovation professorship, Prof. Dr.-Ing. Rucker-Gramm carries out research and teaching projects that focus on sustainable lightweight constructions. Her project focuses on sustainable material recipes and sustainable additive manufacturing processes, such as 3D printing. It thus makes an important contribution to being able to produce and use the indispensable building material concrete in a more CO2-friendly and resource-saving manner.

Prof. Dr.-Ing. Rucker-Gramm implements her project in the university's own laboratory for building materials, building physics and building maintenance. It strengthens the ReSULT-Research Lab for Sustainable Lightweight Building Technologies with a focus on sustainable lightweight construction, contributes to the sustainability strategy of the Frankfurt UAS and promotes the establishment of the doctoral center for digitally integrated engineering.

In Conversation with Prof. Dr.-Ing. Petra Rucker-Gramm

Ms Rucker-Gramm, what do you do in your innovation professorship?

We build a lot with concrete: bridges, canals, skyscrapers and much more. These infrastructure structures, which shape our environment, would not exist in this form without concrete, at least they would look different. We use concrete so often because it can be very strong, is very durable, has a high resistance to moisture, frost and pollutants and can be molded into all sorts of shapes. Those are huge benefits. The problem, however, is that concrete contains cement. A lot of CO2 is emitted during cement production, among other things as a result of an unavoidable chemical reaction. Today, seven percent of global CO2 emissions can be traced back to cement. We have to reduce that.

There are basically two ways to solve the problem. For one, we can replace some of the cement with other materials that give the same reaction product. Calcined clays, whose raw material base is available in large quantities, offer a sensible and sustainable option. In addition, secondary raw materials must remain in focus: waste from other branches of industry, such as fly ash will be until coal combustion is phased out.

The second way is to only use the concrete where its performance is really required. At present, concrete is mostly used over a large area in order to save on manufacturing costs and thus labor costs. The production of geometries appropriate to the load flow does not pay off with traditional concrete production due to the labour-intensive preparatory work. 3D printing offers the potential to bring concrete to the right place in a targeted manner - without this labor-intensive preparatory work. Due to high strength and a dense structure, small component thicknesses can be realized.

So it's about researching a new process and the necessary material properties?

Yes. With conventional processing, the concrete has to be able to do comparatively little. It must have the right consistency so that it can be applied to any part of the prefabricated concrete formwork without any defects and can harden there. It's a bit different when it comes to printing: the concrete first has to flow so well that it can be pumped through the pressure screw. But when it exits the nozzle, it must immediately retain its shape on its own and not flow away. This is a completely new combination of requirements. For this we have to develop the concretes. That's a big challenge.

3D printing is currently a big hype and the subject of research at various universities. So we have to look for a niche. In the ReSULT team we think about which direction we are going. Concrete printing will certainly be used in lightweight textile construction. The contribution made by the innovation professorship is the development of a suitable resource-optimized recipe.

You chose this concrete laboratory as the place to tell about your project. Why?

Here at the university we have a wonderful laboratory with many possibilities. Without all this equipment - high-performance mixer, 3D printer, fresh and hardened concrete examination methods - my research would not be possible.

What do you wish for when you find a good recipe? How to proceed then?

I hope that we will contribute to significantly reducing cement-related CO2 emissions and to planning and building in a resource-efficient manner. The disciplines involved in construction can make a decisive contribution together. I think it's great to have the opportunity to work in a field where you can achieve so much. It really pays off to do research here! It would be great if we, together with the ReSULT research group, developed concrete, applicable solutions that combine 3D printing with lightweight textile construction.

What personal relevance does the project have for you?

With my research I can make a contribution to climate neutrality and the more efficient use of natural resources. As a mother of four children, who should continue to live in an intact environment in the future, these issues are very important to me.

Thank you for the interview!