Nowadays, shock wave processes and their numerical simulation cover a spectrum that ranges from gas-dynamics of super-sonic objects, over air-blast-waves originating from detonations including their interaction with deformable structures, to the effects of shocks in structures, e.g., induced by projectiles or meteorites.

Shock waves in soft matter have increasingly attracted interest in the field of medical treatment of inflammations or of nephroliths. The specific characteristics distinguishing shock waves from ordinary acoustic waves are the extremely short rise times (in the range of nanoseconds, in contrast to microseconds with acoustic waves) and their dissipative nature. Reason for the formation of a shock wave is either the super-sonic motion of an object and the related wave-superposition or the pressure-dependency of sound speed which again leads to wave superposition and steepening of the wave front. As the initiated shock travels into a material, it is reflected at the free surfaces shaping release waves. At locations where several release waves are super-imposed, a tensile pressure state is established which can lead to instantaneous failure, called spallation. Two examples of my shock wave research are provided at the left.

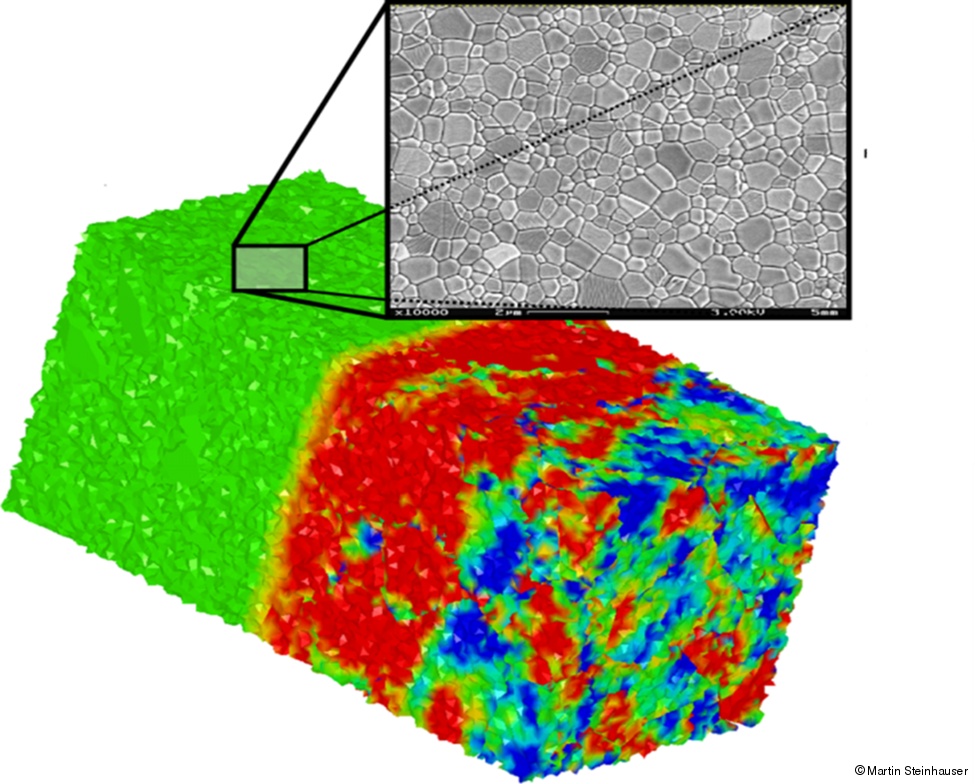

The figure shows a propagating shock wave through a (1.6 x 1.6 x 3.2) μm3 block of Al2O3 with 176 grains at 170 ps after initiation of the shock wave. The color code displays the pressure levels within the range of 1 GPa. Dark colors: high pressure levels, light colors: low pressure levels. The blow-up shows one of the experimental polished micrographs which have been used for our reverse Monte-Carlo optimization scheme, with which we are able to generate very realistic three-dimensional polyhedral grain structures. We then use the obtained statistics in terms of the first 4 moments of the grain area and perimenter from two-dimensional virtual cuts through the power-diagram and compare it with the corresponding moments obtained from experimental micrographs. We then change the gewnerator points of our power diagrams and obtain a different three-dimensional polyhedral grain structure, calculate the statistic again and thus gradually optimize our computer-generated structure with the available experimental data.

Selected publications

A Review of Computational Methods in Materials Science: Examples from Shock-Wave and Polymer Physics

M.O. Steinhauser, S. Hiermaier

Int. J. Mol. Sci. 2009, 10, 5135

A Discrete Particle Method for Simulating Hypervelocity Impact Phenomena

E. Watson, M.O. Steinhauser

Materials 2017, 10, 379

Novel Computer Simulations Addressing the Impact Risks in Space from Orbiting Debris

M.O. Steinhauser

Mater. Sci. Eng. J. 2017, 1, 1005