Our misssion

Most engineering tasks today require expertise in a wide variety of fields and benefit from interdisciplinary collaboration between different specialisms.

The iit enables and promotes interdisciplinary cooperation within the Faculty of Computer Science and Engineering in research and development, in teaching and studies as well as in further education and knowledge and technology transfer.

Current research projects

In this research project, we are investigating the effects of augmented reality on field service (service provided by customer service technicians). We are testing the new technology with data glasses such as the Vuzix M300 or RealWear HMT-1, but also with mobile phones. We identify practical use cases in service and their benefits for the machine manufacturer and the machine user. Through industrial field trials and interviews with experienced users, we identify the barriers and key activities for successfully utilising AR technology in field service. Initial results show, for example, that AR makes it possible for smaller companies to provide worldwide service with high quality and short response times at low cost.

The AR@APPRISE research project is funded by industrial partners and research funds from the Faculty of Computer Science and Engineering.

Contact person: Maike Müller

Augmented reality (AR) technology allows remote experts to connect to a person standing on site at a machine with a smartphone or AR glasses and communicate via live video streams (similar to Skype) with integrated AR functions. AR-based remote services are services that utilise AR technology to support on-site inspections, maintenance, repairs or training on machines and systems installed worldwide from a distance (remotely).

In the Augmented Reality-based Remote Service Business Models (ARemoS) research project, design options for AR-based remote service business models are being identified and transferred into a taxonomy (empirical classification system). From this, a business model typology (conceptual classification system) of business models will be developed. This will be achieved through interviews with employees responsible for service from as many mechanical and plant engineering companies as possible.

The results can be used in practice as a tool for the future design of AR-based remote service business models.

Now is the right time to transfer our preliminary work into business practice, because the travel restrictions imposed by COVID-19 are leading to massive losses in the service business of the mechanical and plant engineering industry. AR-based remote services can also save CO2 and secure jobs through additional digital services. [The research project is funded by the "Research for Practice 2021" funding line with EUR 40,000].

Contact person: Stefan Ohlig

In the RoBoCut-AR research project, we are working with the Bremen-based technology start-up RoBoTec PTC (www.robotec-ptc.com) to develop an AR-based remote service concept for fully autonomous ornamental and crop production with the RoBoCut. RoBoCut experts can remotely support local operators of the RoBoCut through real-time collaboration via video streams and integrated AR functions. This reduces unnecessary travelling by service technicians. It also ensures short downtimes and high productivity.

The project is being funded by the Federal Ministry for Economic Affairs and Energy over a period of 24 months from 1 October 2020 to 30 September 2022 with 171,300 euros as part of the Innovation Programme for Business Models and Pioneering Solutions. (Funding reference number: 16GP100102).

Contact person: Stefan Ohlig

The aim is to develop a new process for the pre-separation of organic components from biogas and the optimisation of downstream CO2 purification for energy- and resource-optimised biogas upgrading.

Together with our industrial partner Carbotech Gas Systems GmbH, we are developing process models for this purpose. Thanks to the industrial co-operation, these can be validated at all levels of scale transfer:

- Laboratory scale

A new, innovative laboratory setup was developed by the research group and set up in the process technology centre. An der Anlage können beliebige Adsorbentien mittels Durchbruchanalyse charakterisiert werden. - Pilot scale

With the industrial partner's pilot plant, any pressure swing adsorption processes can be run cyclically. The previously individually validated process steps can be interconnected here. The process model can thus be resiliently supplemented with real factors and thus transferred to scale (upscale). - Industrial scale

The process model can be finally validated by commissioning tests on the finished system at the customer's premises.

Contact person: Thomas Welter

The aim is to develop a new process for recovering solvents in the coating industry. It is expected that this will significantly reduce costs compared to conventional technologies and at the same time protect the environment.

To achieve this, the Frankfurt University of Applied Sciences (FRA-UAS), together with its industrial partner Rafflenbeul Anlagenbau GmbH, is initially determining the feasibility and limits of the process approach on a pilot plant scale. A pilot plant will then be designed on this basis. This will be planned by Rafflenbeul and built and operated on the premises of Anton Debatin. In this way, the results from the pilot plant trials will be verified on an industrial scale.

The new process approach is a multi-stage concept. In a first step, the solvents in the exhaust air are concentrated by adsorption, then bound by absorption in a glycol-based detergent, before being recovered in a final step by distillation and condensation and reused in the coating process. Fra-uas is responsible for the adsorptive concentration of the solvents.

The project is being funded by the State of Hesse's Offensive for the Development of Scientific and Economic Excellence (LOEWE).

Contact person: Niklas Döring

Results:

1.) ML models enabled much-prolonged cleaning intervals saving time and money

2.) A better understanding of critical process parameters was achieved

Contact person: Fatima Butt, Anahita Farhang

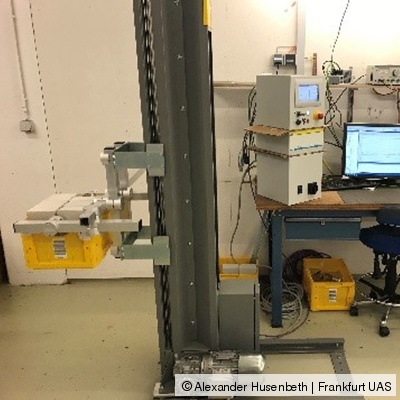

Results:

- The lifting device had to be calibrated by the operator with a proper counterweight

- Obtained actuator data from Beckhoff CX9020 Ethernet control system for different configurations during training

- Thus, collected data proper and improper configurations

- Machine Learning Goal: predict configuration from sensor data and trigger warning in case of improper configuration

Contact Person: Jörg Schäfer

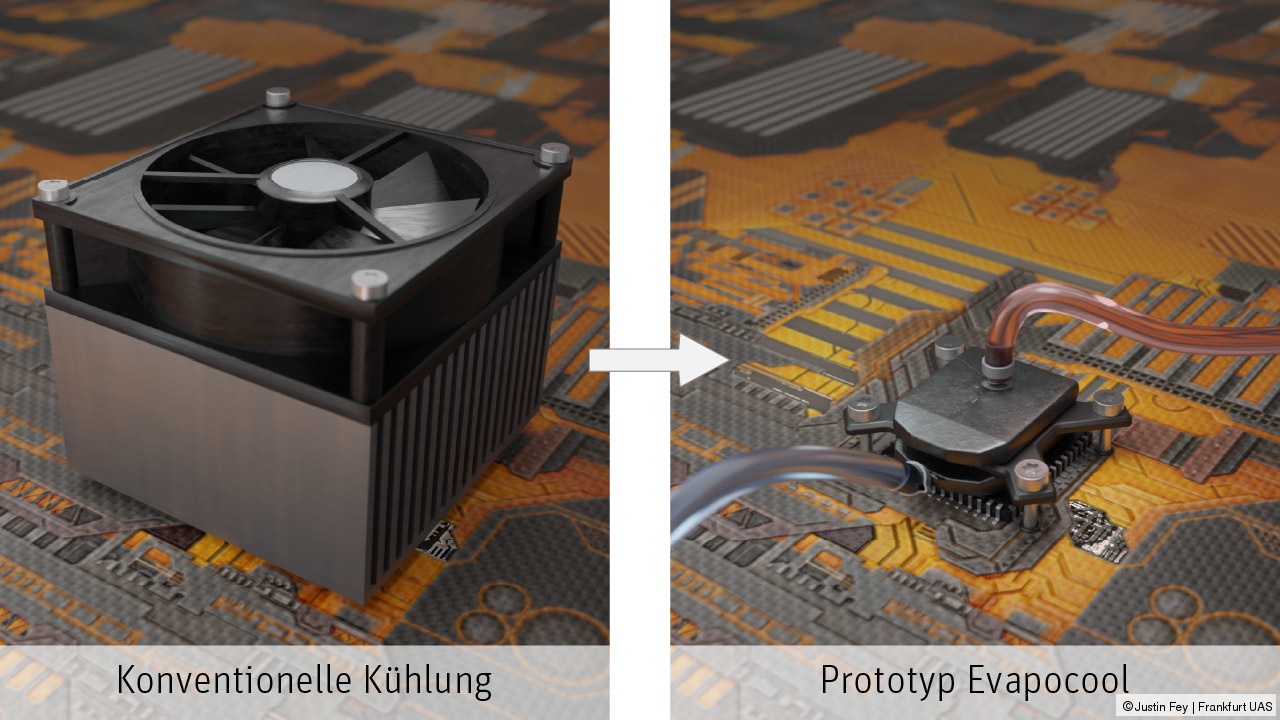

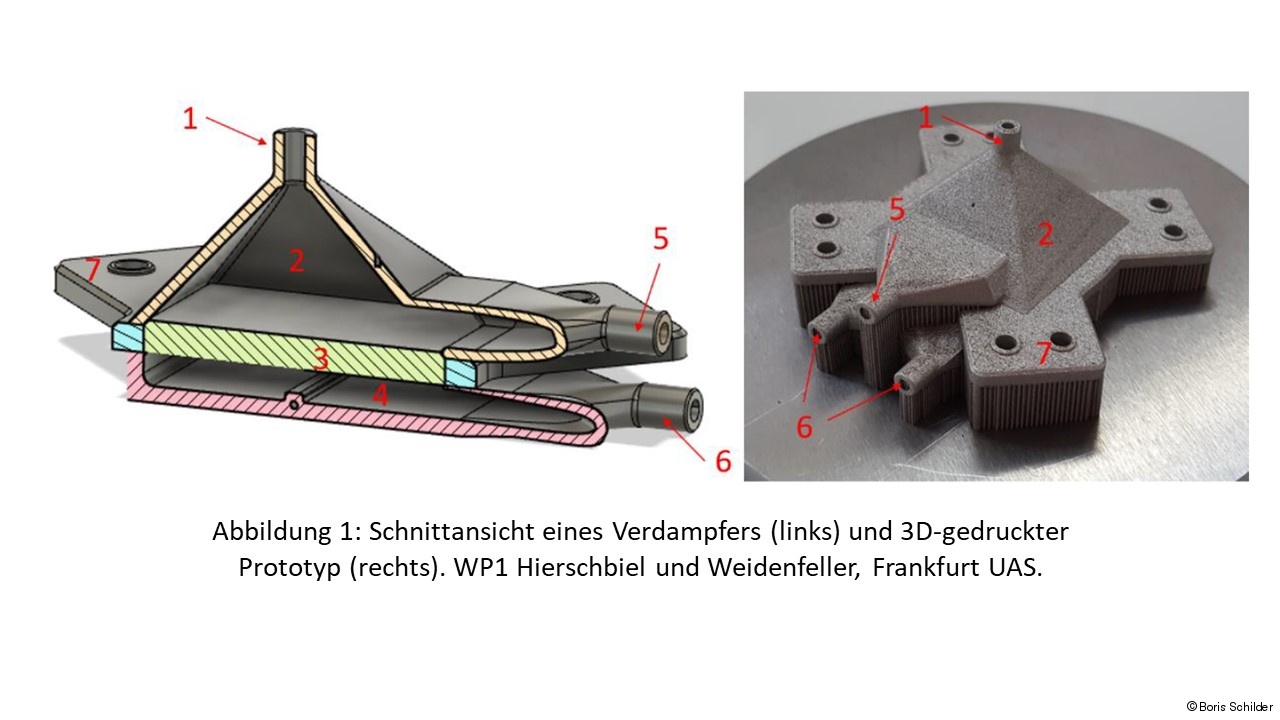

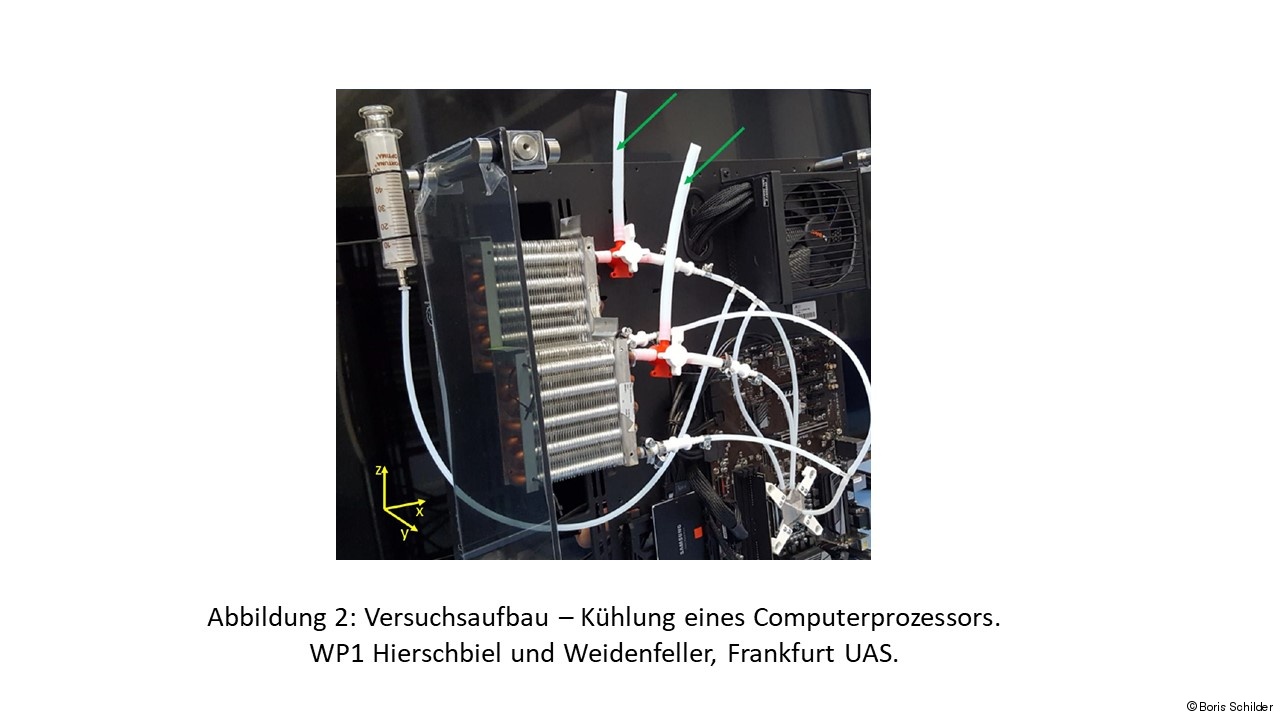

High-performance electronics generate high heat flows that are usually dissipated by air-based cooling concepts. However, air cooling has the disadvantages that it offers only limited cooling performance, requires a lot of space, the fans consume energy and can be noisy.

Evaporative cooling offers the highest heat transfer performance and can operate passively and therefore silently.

Current evaporation-based cooling concepts are mostly based on the "heat pipe" concept. Water is often used as a cooling medium in heat pipes. To cool high-performance electronics down to acceptable temperatures (e.g. 70 °C), low system pressures and thus complex evacuation as well as a tight, pressure-resistant system are required. Therefore, the medium is transported in metallic pipes, which do not allow a flexible design of the fluid transport.

Our goal is to develop a novel evaporative cooling concept using a synthetic cooling medium that has a low boiling temperature (about 50 °C) at ambient pressure. This allows the system to operate at ambient pressure and eliminates the need for pressure-resistant walls. In contrast to a heat pipe, a capillary structure is only required in the evaporator, so normal hoses can be used for fluid transport.

Contact: Prof. Dr. Boris Schilder, Justin Fey

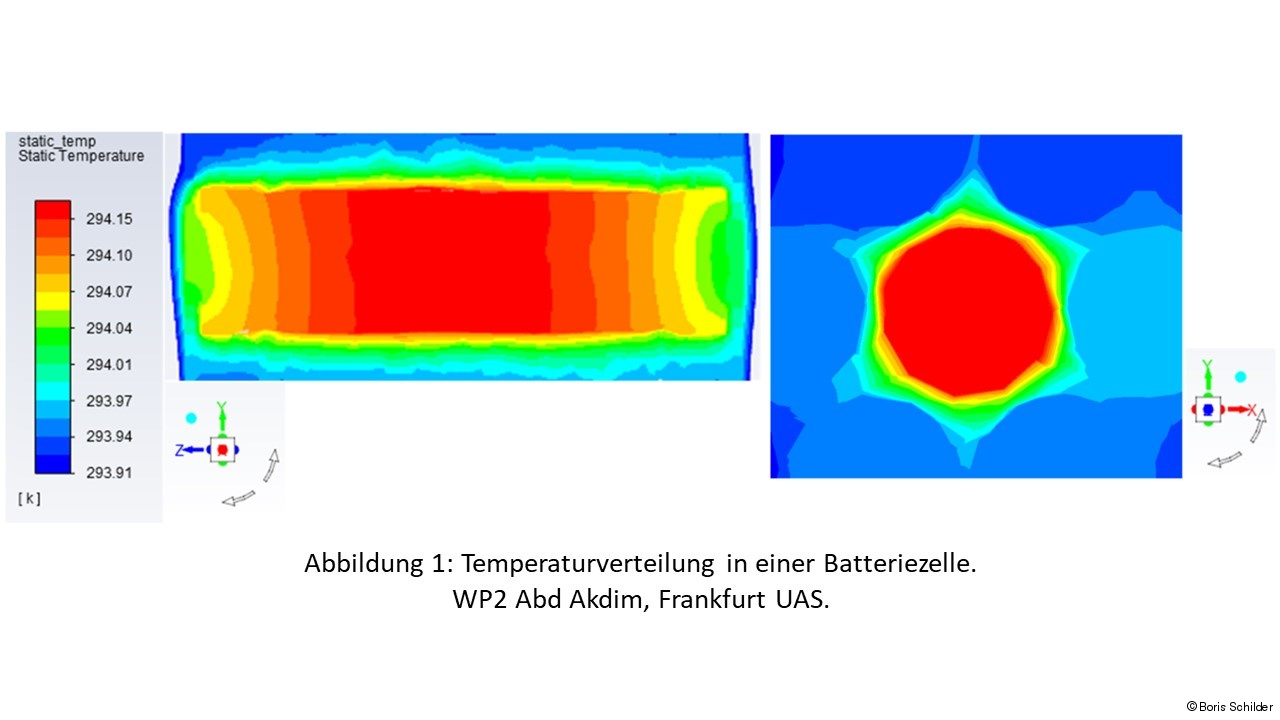

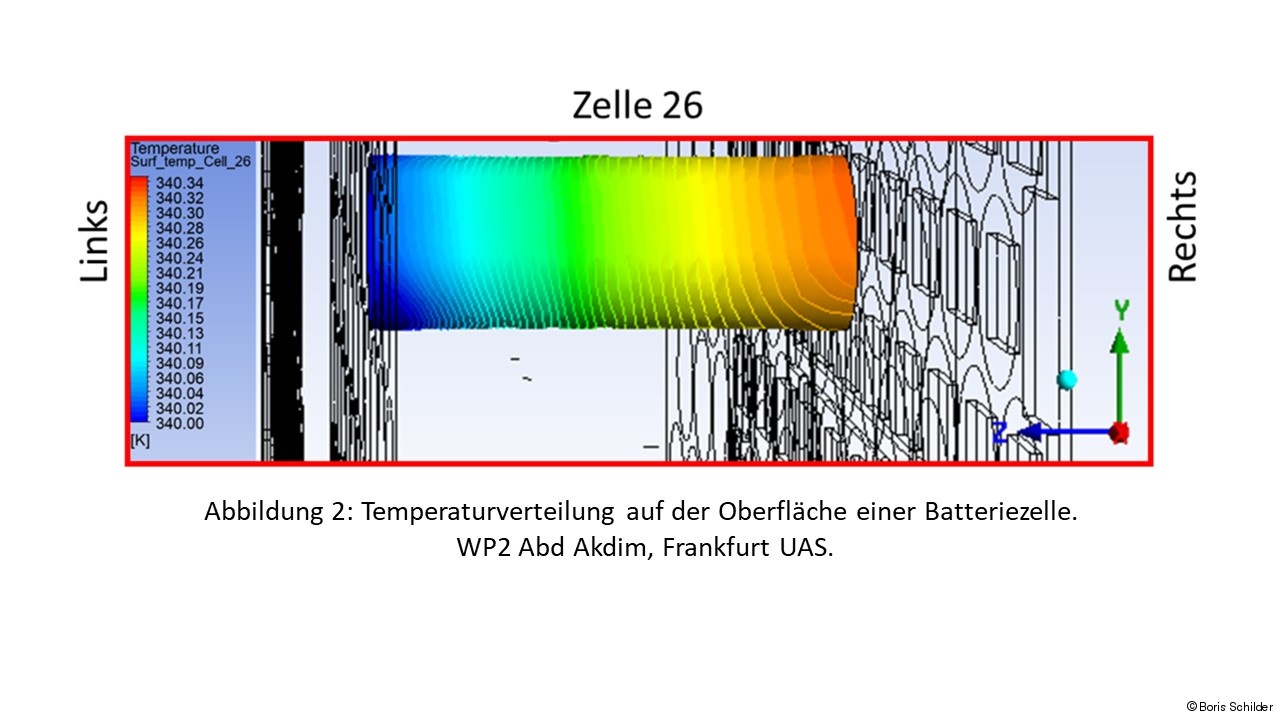

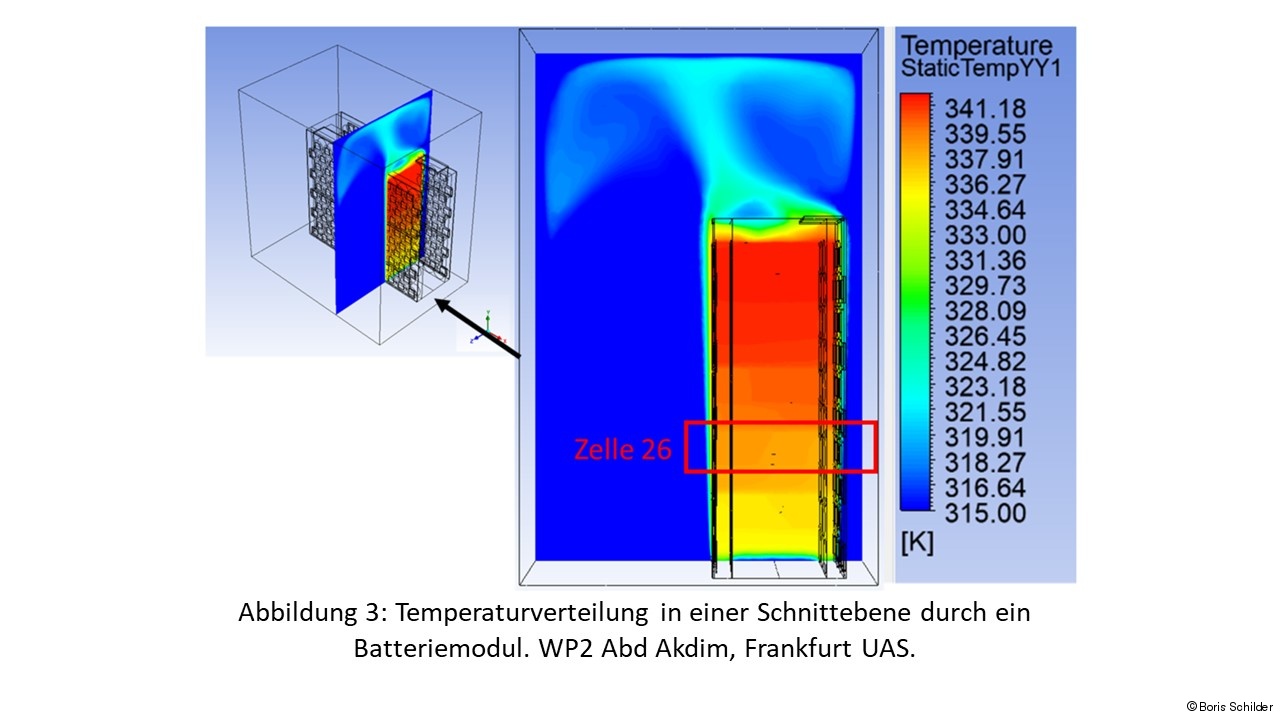

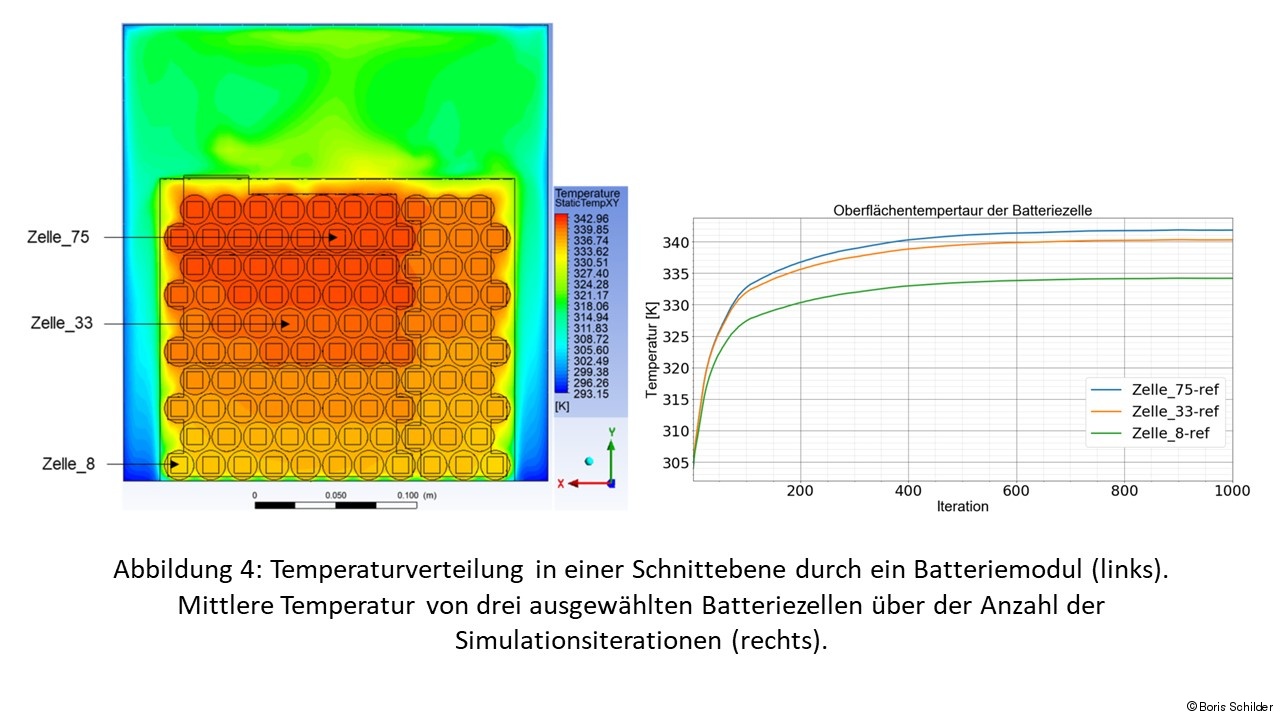

Batteries in electric vehicles must be able to deliver and absorb high currents during driving and charging. This generates heat in the battery, which leads to a rise in temperature. The aging and performance of lithium-ion batteries strongly depend on the temperature and the temperature distribution within the battery.

We are using simulations and experiments to investigate heat generation and heat transport in battery modules. The goal is to develop thermal management concepts that enable the best possible heat removal and the most homogeneous temperature in the battery. This can have a positive influence on the service life, energy density and costs of batteries.

Contact: Prof. Dr. Boris Schilder

In March 2017, Frankfurter Entsorgungs- und Service GmbH (FES) and Frankfurt UAS entered into a research partnership to conserve resources while improving the quality of air and life for people in the city. With the support of the state of Hesse, an innovative waste collection vehicle with a new natural gas-electric hybrid drive will be purchased in a two-and-a-half-year pilot project and analysed for potential fuel savings, pollutant emissions and noise pollution.

To this end, the mobile exhaust and acoustic measurement technology of the vehicle and NVH laboratory is being used to record the emissions of a conventional waste collection vehicle in daily collection operations for the first time and include them in the comparison. The refuse collection vehicle, which is usually powered by a diesel engine, is in constant stop-and-go operation in the city and is correspondingly inefficient. Added to this are pollutant emissions such as the nitrogen oxides recently discussed in connection with diesel engines and noise pollution, which should not be neglected.

The aim of the measurements is to sound out the technical possibilities for more environmentally friendly and quieter waste disposal and thus to be able to draw conclusions about all inner-city commercial vehicle traffic. As a rapidly growing conurbation, the Rhine-Main region has an important role to play in environmental and climate protection. Accordingly, the use of new vehicle concepts could become trend-setting. The project is co-financed with 421,900 euros by the Hessian Ministry of Economics, Energy, Transport and Regional Development as part of the "Promotion of electric mobility" funding programme (HA project no.: 523/17-05).

Publications

- Binder de Serdio, A., Stegelmeyer, D., Flemming, L., Mishra, R. (2025). „Process Models for the development of Data-Driven Industrial Services: Insights from a Systematic Literature Review.” In: Conference Proceedings of the 5th International Conference on Maintenance and Intelligent Asset Management ICMIAM 2024, Manipal, India. In print.

- Müller, M., Ohlig, S., Stegelmeyer, D., Mishra, R. (2024). "Comparing Adopter, Tester, and Non-adopter of Collaborative Augmented Reality for Industrial Services". In: Yang, XS., Sherratt, S., Dey, N., Joshi, A. (eds) Proceedings of Ninth International Congress on Information and Communication Technology. ICICT 2024 2024. Lecture Notes in Networks and Systems, vol 1011. Springer, Singapore. https://doi.org/10.1007/978-981-97-4581-4_10

- Binder de Serdio, A M, Stegelmeyer, D, Butt, F S (2024). „Early Indicators of Project Abandonment in Industry-Academia Collaborations: Developing an Assessment Framework for Industrial Data Science Projects.” In Proceedings of the 10th Spanish-German Symposium on Applied Computer Science (SGSOACS 2024), Cádiz, Spain. https://zenodo.org/doi/10.5281/zenodo.11916306

- Ohlig, S., Breitkreuz, D., Aliyu, A., Mishra, R., Stegelmeyer, D. (2024) „Towards a taxonomy of design options for augmented reality-based remote service business models.“ Engineering Management in Production and Services, 16(2), 128–147. https://doi.org/10.2478/emj-2024-0018

- Müller M, Ohlig S, Stegelmeyer D (2024) „Remote Augmented Reality im Maschinen- und Anlagenbau einführen: Management Summary einer Studie mit 130 Industrieunternehmen.“ WHITE PAPER, Frankfurt University of Applied Science, Frankfurt am Main. https://doi.org/10.48718/xp3h-4j47

- Ohlig, S., Müller, M., & Stegelmeyer, D. (2024) „Augmented Reality Remote Service Business Models in the Mechanical and Plant Engineering Industry. Results of an Interview Study with 36 Manufacturers“ (WHITE PAPER 3). Frankfurt am Main. Frankfurt University of Applied Sciences. https://doi.org/10.48718/67fr-ay51

- Ohlig, S., Breitkreuz, D., Mishra, R. & Stegelmeyer, D., 2023. „Business Model Research on Industrial Augmented Reality: A Systematic Literature Review on the Current State and Future Research Areas” In L.-C. Tang (Ed.), Advances in Transdisciplinary Engineering. Industrial Engineering and Applications (pp. 489–499). IOS Press. https://doi.org/10.3233/ATDE230074

- Butt, F. S., Schäfer, J., Wagner M. F., Stegelmeyer, D. & Gómez-Ullarte Oteiza, D., 2023.„Application of CRISP-DM and DMME to a Case Study of Condition Monitoring of Lens Coating Machines” In 2023 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT), Brescia, Italy, 2023, pp. 409-414 https://doi.org/10.1109/MetroInd4.0IoT57462.2023.10180178

- Stegelmeyer, D., 2023. „Gastbeitrag: Serviceprodukte entwickeln“ In VDMA e.V. (Ed.), VDMA Magazin (Vol. 102, p. 16). VDMA Verlag.

- Müller, M., Stegelmeyer, D. and Mishra, R., 2023. „Development of an augmented reality remote maintenance adoption model through qualitative analysis of success factors” Operations Management Research. https://doi.org/10.1007/s12063-023-00356-1

- Büdding, Y., Krimm, J., Marschner, H. and Techen, H., 2022. "Automatisierte Bestimmung geeigneter Vorbeifahrtgeräusche zur Charakterisierung innerstädtischer Schallfelder." Lärmbekämpfung, Vol. 17(3), pp. 77-81.

- Büdding, Y., Krimm, J., Marschner, H. and Techen, H., 2022. "Automatisierte Erkennung von vergleichbaren Vorbeifahrten von Straßenfahrzeugen im laufenden Verkehr." Tagungsband DAGA 2022 - 48. Jahrestagung für Akustik. Stuttgart, pp. 596-598.

- Krimm, J., Techen, H., Marschner, H. and Büdding, Y., 2022. "Akustische Planungsparameter zur Bewertung der leiseren Stadt."Tagungsband DAGA 2022 - 48. Jahrestagung für Akustik, Stuttgart, pp. 59-61.

- Möwis, G., Stegelmeyer, D., Struyf, B., & Matthyssens, P., 2022. "Leveraging ecosystem partnerships for Industry 4.0-enabled value creation: A Delphi-study." In V. Kirov & B. Malamin (Chairs), Inclusive Futures for Europe, addressing the digitalisation challenges: BEYOND4.0 Scientific Conference Sofia 2021 Proceedings, Sofia.

- Breitkreuz, D., Müller, M., Stegelmeyer, D., & Mishra, R., 2022. „Augmented Reality Remote Maintenance in Industry: A Systematic Literature Review”. In L. T. de Paolis, P. Arpaia, & M. Sacco (Eds.), Lecture Notes in Computer Science (LNCS) (Vol. 13446, pp. 287–304). Springer. https://doi.org/10.1007/978-3-031-15553-6

- Maiser, E., Küster, A., Thomin, P., Moller, B., Kirstgen, A., Lerch, C., & Stegelmeyer, D. 2022. „ Future Services 2035: Zukunftsbilder für den Maschinen- und Anlagenbau“ (VDMA Future Business, Band 8). Frankfurt am Main.

Janssen, S.; Launer, M..; Beckmann, J.; Stegelmeyer; D., 2021. „Remote-Inbetriebnahme. Leitfaden und Vertragsmuster“. 1. Aufl.: VDMA Verlag, Frankfurt.

- Marschner, H., Krimm, J., Techen, H., Büdding, Y. and Fiedler, R., 2021. "A detailed investigation on three-dimensional sound emittance of today’s motorised vehicles in urban contexts." Euronoise (2021), Madeira . Lissabon: Sociedade Portuguesa de Acústica (SPA), pp. 1040-1049

- Müller, M., Stegelmeyer, D., & Mishra, R., 2020. "Introducing a Field Service Platform". In: A. Ball, L. Gelman, & B. K. N. Rao (Eds.), Smart Innovation, Systems and Technologies. Advances in Asset Management and Condition Monitoring (Vol. 166, pp. 195–205). Cham: Springer International Publishing. https://doi.org/10.1007/978-3-030-57745-2_17

- Ohlig, S., Stegelmeyer, D., Mishra, R., & Müller, M., 2020. "Exploring the Impacts of Using Mobile Collaborative Augmented Reality on the Field Service Business Model of Capital Goods Manufacturing Companies". In: A. Ball, L. Gelman, & B. K. N. Rao (Eds.), Smart Innovation, Systems and Technologies. Advances in Asset Management and Condition Monitoring (Vol. 166, pp. 473–484). Cham: Springer International Publishing. https://doi.org/10.1007/978-3-030-57745-2_40

- Husenbeth, A., Berens, G., Stegelmeyer, D., 2019. "Die Anwendung des maschinellen Lernens – Fokus Interaktionsprozess in Predictive Maintenance Projekten". In: Henke, M. (ed.), Tagungsband des 18. InstandhaltungsForums, pp. 78-88.

- Marschner, H. and Hartmann, P., 2019. Silent Green: auf dem Weg zum Müllauto, das auch die Luft reinhält.Technik & Mensch: VDI Frankfurt-Darmstadt aktuell, (2), pp. 3-5.

Müller, M., Stegelmeyer, D., & Mishra, R., 2018. "Investigations on augmented reality based maintenance practices within SMEs". In: P. Heyns, P. Van Vuuren, G. Van Schoor, & R. Rao (Chairs), Proceedings of the 31st International Congress and Exhibition on Condition Monitoring and Diagnostic Engineering Management: COMADEM 2018, Sun City, Rustenburg, South Africa.

- Marschner, H., Leibold, P., Pfaff, A. and Maggi, G., 2017. "Schwingungen und Geräusche". In: Breuer, B. and Bill, K. H. (eds.), Bremsenhandbuch : Grundlagen, Komponenten, Systeme, Fahrdynamik. Springer Vieweg, pp. 627-648.

- Döring, N., 2017. "Neuartiges Verfahren zur Rückgewinnung von Lösemitteln in der Druckindustrie senkt Kohlendioxidemissionen". In: Technik & Mensch, VDI.

- Marschner, H., Leibold, P., Pfaff, A. and Morschel, C., 2016. "Investigation of the interaction mechanisms of friction excited stick-slip-vibrations on the example of brake groaning and analogue vibration phenomena", Internationales μ-Symposium Bremsen-Fachtagung (2016), Bad Neuenahr. In: Breuer, B. (ed.), VDI, pp. 206-224.

- Marschner, H., Leibold, P., Pfaff, A. and Morschel, C., 2016. "Untersuchung der Wirkmechanismen reiberregter Haft-Gleit-Schwingungen am Beispiel des Bremsenknarzens und analoger Schwingungsphänomene", Internationales μ-Symposium Bremsen-Fachtagung (2016), Bad Neuenahr. In: Breuer, B. (ed.), VDI, pp. 84-104.