Manufacturing companies bear a special responsibility towards environmental protection since it is primarily industrially manufactured products that can have a massive impact on the environment during their service life.

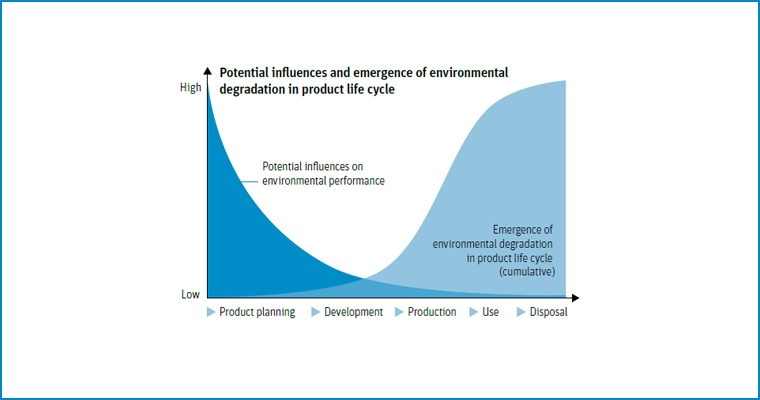

Particularly in the early stages of product planning and development, the choice of materials, for instance, can substantially influence parameters such as energy consumption and emissions. In this context, defining the expected process characteristics during the stages of a product’s service life can have the most effective impact over its entire life cycle.

The EcoDesign and Sustainable Product Development modules introduces students in the General Mechanical Engineering (MA), Mechanical Engineering (BA) and Product Development and Technical Design (BA) study programs to the methodologies used for the environmental optimization of technical products.

EcoDesign is the proactive, holistic ecological, economic and technical optimization of products, taking into account their entire life cycle. “Eco” stands for ecological and economic, underscoring the demand for environmentally friendly and commercially sustainable products in view of the truism that nothing is as futile in terms of environmental sustainability as a product that is useless to the customer.

The basis for understanding the root causes of environmental degradation is life cycle thinking: Product developers must give early consideration to possible processes and their impacts on all stages of the life cycle, including selection, design and optimization from an environmental compatibility standpoint. Here the fundamental tenet of EcoDesign applies of always taking into account all stages of a product’s life cycle (material production, fabrication, utilization, recycling/disposal). Failure to do so can deliver distorted – if not patently erroneous – results, thereby increasing the risk of setting the wrong development goals and in the process jeopardizing the product’s environmental performance and even its commercial success.

Every constructive measure ultimately influences the environmental degradation in a product’s life cycle and interacts with other environmental impacts in the same or other stages of its life cycle. Accordingly, every measure must be evaluated not only from a technical and economical perspective but also from an environmental standpoint, e.g., through life cycle assessment. Negative interactions in particular, whereby an environmentally beneficial measure per se results in undesirable environmental effects some-where else, must be flagged in good time because in the worst case scenario they may lead to an increase in the overall environmental burden.